Home / All

News

- Refined Shredding of Waste Plastics to Help Recycle “White Pollution” into Resources!Different types of recycled plastics have different recycling sources due to their different application fields.Dec 25,2023

At present, waste PET, waste PE, and waste PP are the main components of waste plastic recycling inChina, accounting for 70% in 2021. - Cost Reduction Battle! Another Cement Factory SRF Alternative Fuel Processing Center Has Been Put Into Operation!SRF alternative fuel is a "super weapon" for cement companies to reduce costs and save coal.Dec 18,2023

- Discarded Clothes Rebirth: The Waste Textile Transformed Into A Treasure BowlRDF/SRF ALTERNATIVE FUEL PROCESSING TECHNOLOGYDec 18,2023

- The Real Fact: High-quality SRF Alternative Fuel Should Look Like This!High-Quality SRF Alternative Fuel Could Reduce Coal CostsDec 15,2023

- Good News: Biomass SRF Alternative Fuel Processing Systems Project Has StartedA Good Way for Cement Industry to Reduce Coal CostDec 15,2023

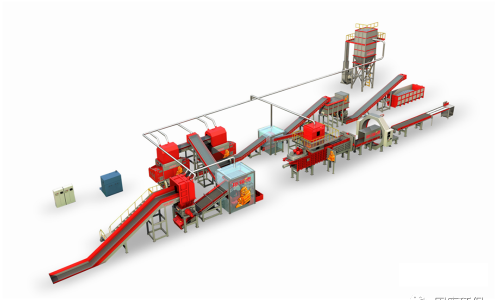

- Harden efficient and resource-based solutions help the cause of environmental protectionHarden general industrial solid waste resource treatment system can produce waste cloth, leather scraps, waste fabrics, waste plastics and other general industrial solid waste generated in light industrial parks into a high calorific value alternative fuel SRF/RDF, with a thermal replacement rate of more than 70%, which can be used to replace coal combustion in industrial kilns, achieving a "huge transformation" of waste toAug 31,2023

- The first RDF/SRF alternative fuel preparation system for decoration waste in Yangjiang, Guangdong Province has been put into operationIn this project, the raw material is decoration waste, which is processed into RDF/SRF alternative fuels with a size of about 80mm. The combustion calorific value is about 5000 large calories, which is more than 80% of standard coal, and the CO2 emissions are only one-quarter of those of coal. Therefore, it is an important "weapon" for all coal-fired enterprises and construction enterprises to face the "carbon reduction" test.Aug 8,2023

- After an alternative fuel experiment by a Chinese company, it was concluded that every 1.74t of alternative fuel can save 1t of coal.a Chinese company conducted an experiment of SRF alternative fuel used in industrial kilns, exploring "How much coal can be saved by the use of alternative fuel?" in the process data and practical results.Aug 1,2023

- Chinese paper enterprises to reduce the cost of secrets!Paper Mill Waste Recycling Disposal System!Har Der alternative fuel preparation technology can easily solve more than 100,000 tons of paper waste.Jul 24,2023

- A case study of a system to produce alternative fuels from industrial waste and bulky waste in ChinaSolid waste is used, and the final discharge is SRF alternative fuel.Jul 17,2023

- Cost reduction, efficiency, low carbon environmental protection! Cement industry 2023 super hot "alternative fuel preparation technology"So what should be done?Jul 12,2023

Solid waste composition complex, low calorific value problems? - Is it possible for alternative fuels to replace traditional fossil fuels as the mainstream?If you were a coal-burning company, would you like to choose $60 alternative fuels per ton or $180 coal fuels per ton?Feb 27,2023

News Group