RDF/SRF Preparation Technologies Help MSW (Municipal Solid Waste) Size Reduction, Harmless and Resource Utilization

China

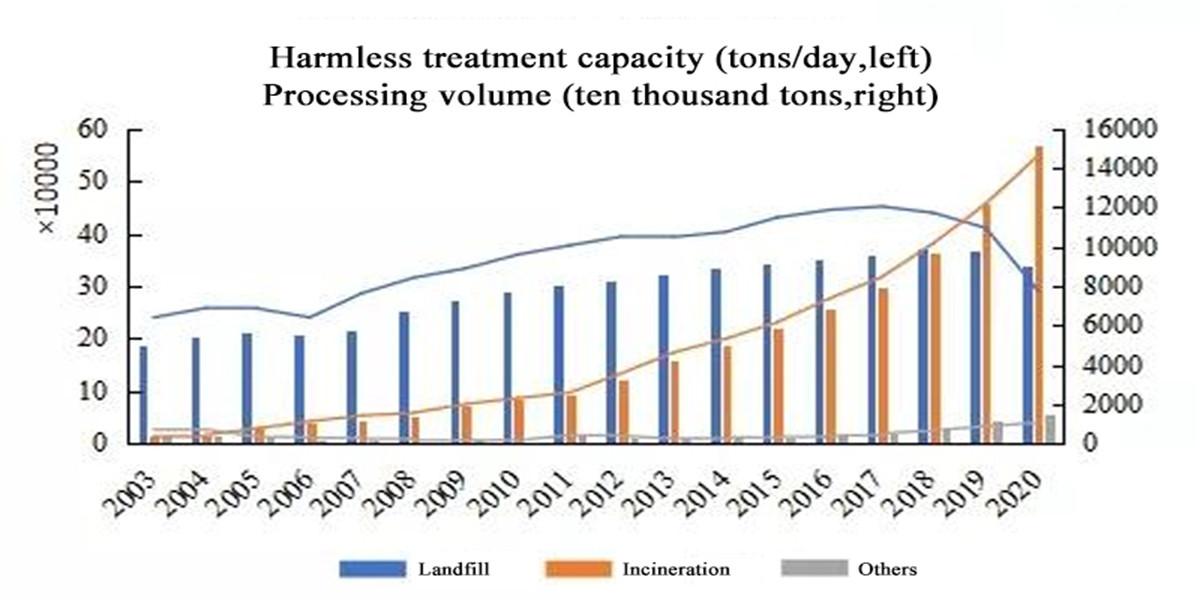

has carried out comprehensive garbage classification since 2019. By the end of

2021, the harmless treatment capacity of the national MSW (municipal solid waste)

has reached 994,900 tons/day, and the harmless treatment rate is 99.7%. Among

them, refined treatment such as size reduction, harmless treatment and resource

recovery has become an important direction for the future development of the

municipal solid waste industry.

Harmless

Treatment of MSW

After

the MSW is correctly classified, except a small part can be recycled, the rest

of the waste through landfill, incineration and other ways for harmless

treatment. Incineration treatment capacity is also improving year by year.

After 2019, it has surpassed landfill treatment and become the first way of

harmless treatment of MSW.

What

is Resource Utilization of MSW

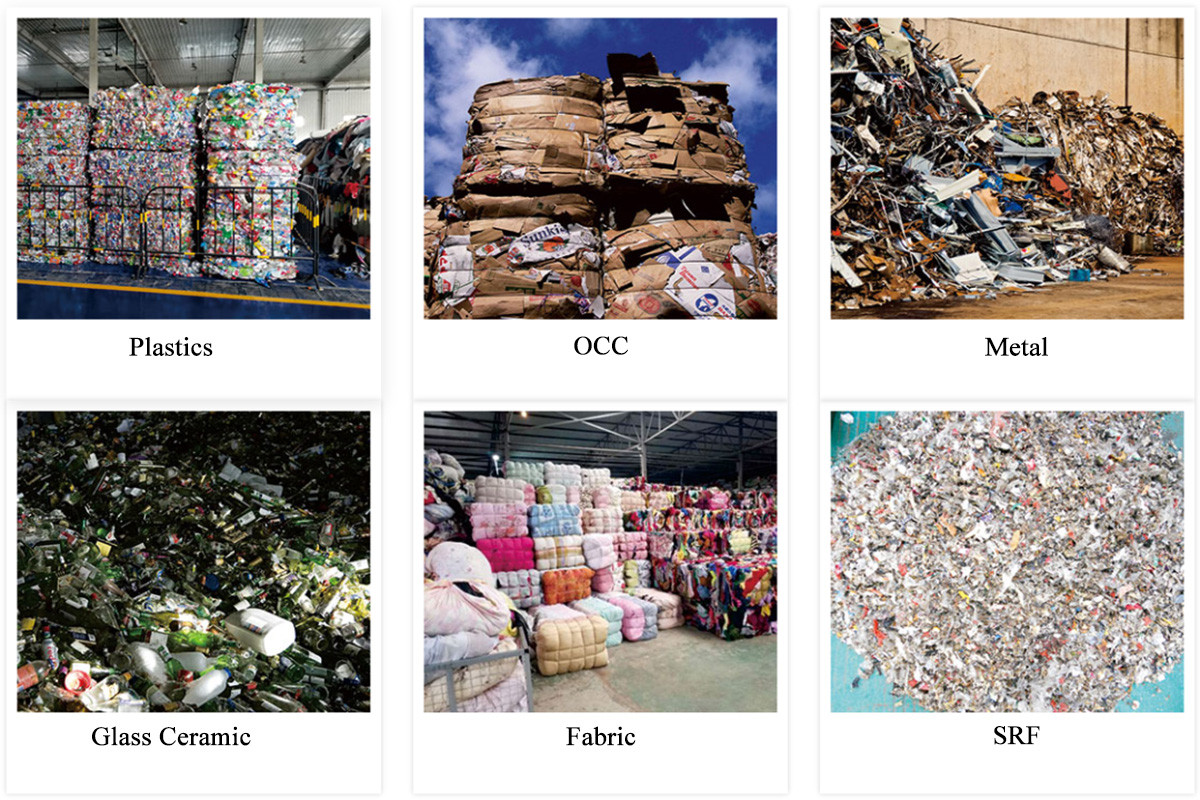

Mixed

MSW contains a large number of recyclable beverage bottles, metal, paper and

other renewable resources, which can be recycled, treated and reused. The

content of perishable waste, mainly kitchen waste, accounts for 40-60%, which

can be used as biomass energy. The largest proportion is high calorific value

fuels, which can be prepared as RDF/SRF (alternative fuels) to reduce

the use of coal.

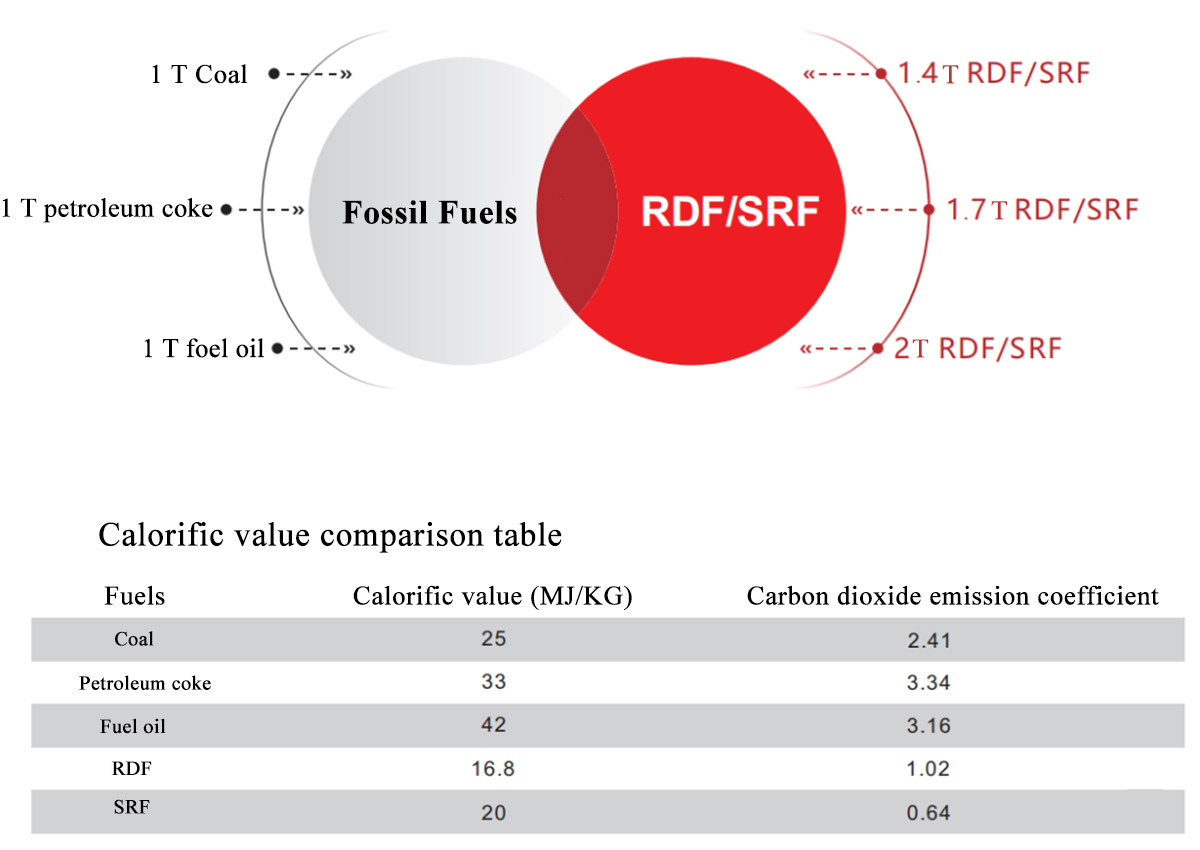

RDF/SRF (alternative fuels) as a new

way of waste reduction, harmless and resource utilization under the background

of Carbon Peaking and Carbon Neutrality Goals, having the similar

combustion efficiency with fossil fuel, but with lower carbon emissions. RDF/SRF

(alternative fuels) has become a new trend of harmless and resource

utilization of MSW in the future.

How

to Produce SRF from MSW?

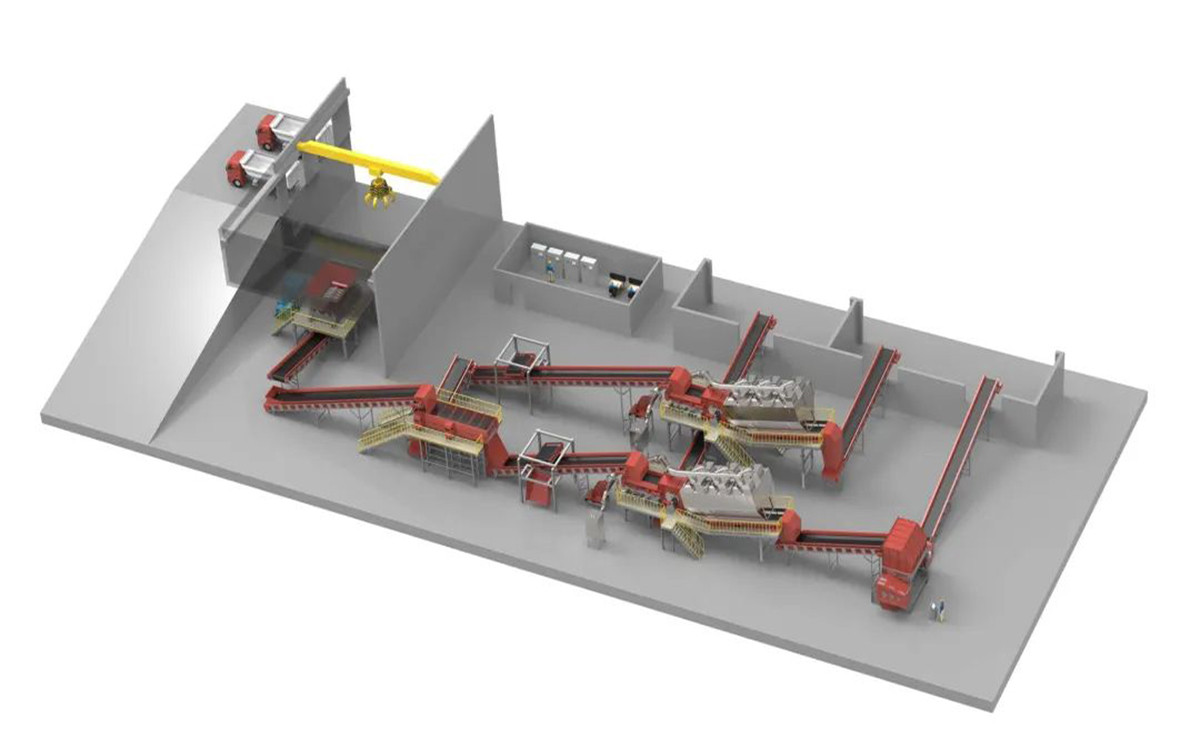

As

a solid waste pretreatment equipment provider in the solid waste processing

industry for over 10 years, Harden has provided complete sets of RDF/SRF

Preparation Systems and Equipment for the Recycling Sorting, Organic

Extraction, and Fuel Preparation of RDF/SRF. At present, the

RDF/SRF Preparation System provided by Harden has been applied in waste

transfer stations, resource utilization centers and cement manufacturing

industry.

In

the SRF Preparation System, the MSW will be processed into high-quality

alternative fuel. The whole system adopts modular designs containing shredding, conveying

and sorting, which results in high processing efficiency and lower operation

cost.

In

this system, the processed MSW is sent to the first stage for coarse shredding,

and then the shredded material is processed by screening, magnetic separation,

wind separation and other fine processing processes to get available metals,

light substances and heavy substances. The light material is then transported

to secondary shredding for fine shredding, resulting in 30-80mm high-quality alternative

fuel (SRF).

With

the acceleration of the construction of Waste-free City and Waste-free

Bay Area, the harmless treatment rate of MSW will reach above 99.9% by

2025. The RDF/SRF Preparation System from Harden will help size reduction,

harmless and resource utilization of MSW through continuous innovative research

and development.