Waste Plastic Shredder for Plastic Recycling and Plastic Remake

Waste plastic is one of the most valuable resources if recycleed in a proper way

Waste plastic can be classified and shredded to remake plastic, produce fuel for plant and generate electricity for power plant, etc. Waste plastic shredding is a critical step to manage various kinds of waste plastic, it helps to reduce the space for storing the bulky waste plastic, lower the transportation cost in the meantime, minor plastic granulates are good for the further waste plastic management.

Harden Serves a Variety of Waste Plastic Recycling Plant

If you’re just looking for plastic shredding machines, you’re at the right place. Harden has designed and manufactured technical plastics shredders that meet virtually all plastics processing challenges including industrial plastic scrap. With years of plastic shredding experiences, Harden carries thousands of successful waste plastic shredding like PET plastic, plastic scrap and production waste, automotive components, etc.

Our plastic shredding machines can be found in the largest plastics recycling plants and in the smallest. Post-consumer plastics recyclers, post-industrial plastics recyclers, and companies that recycle both, consistently choose Harden shredders to do it more profitably.

Why Plastics Recyclers and Plastics Processors Prefer Harden's Plastic Shredders?

Because of their advanced technology, high and stable performance, ease of operation, and ease of maintenance.

Advanced technology-Harden introduced the German technology and combined it with superb manufacturing itself, producing the high-quality waste plastic shredders. We provide service for both plastic recyclers and plastic processors or any association which has waste plastic to dispose of.

High and stable performance-Harden versatile waste plastic shredder can shred various kinds of waste plastic and maintain a stable performance during all the working time. Waste plastic shredder can be driven by either electric or hydraulic station which depends on waste plastic materials or customer's requirements.

Ease operation and maintenance- Harden's one-touch start and auto stop greatly simplifies the operation and reduces the labor cost. Knives of the waste plastic shredder can be repaired by welding to lower the maintenance cost.

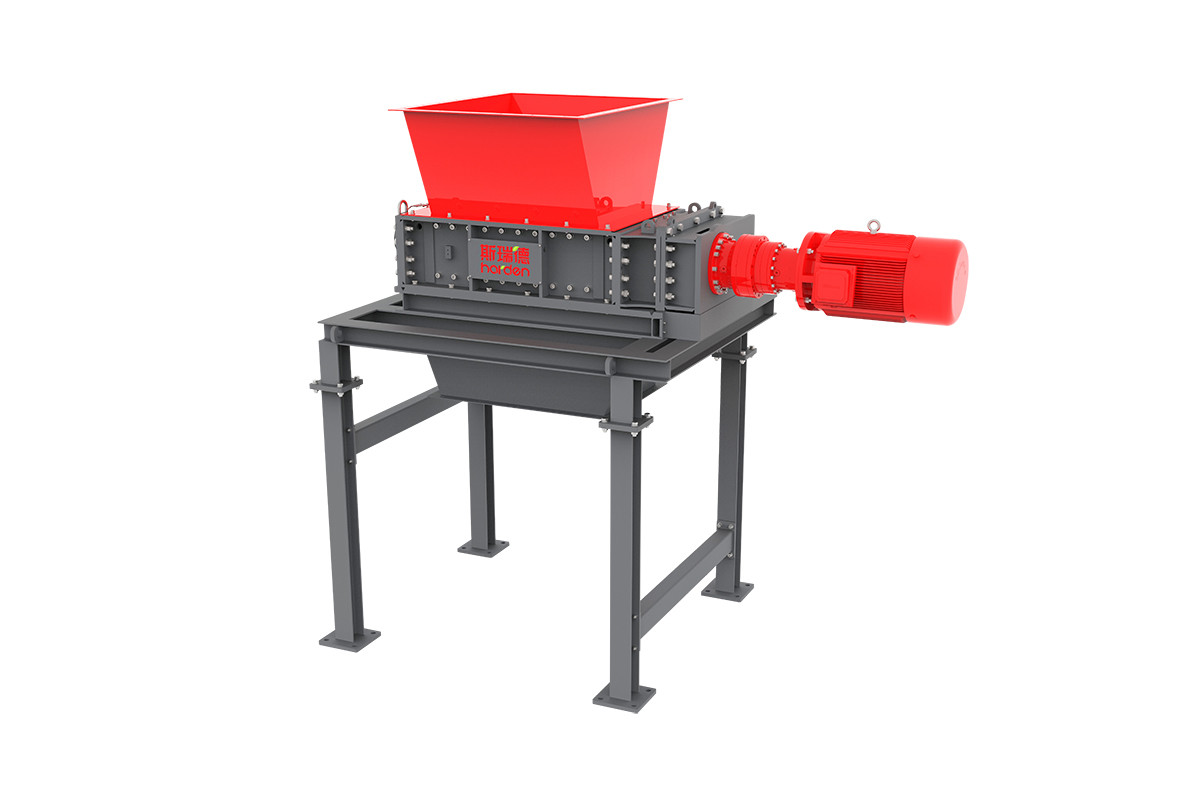

Recommended Harden's Waste Plastic Shredder

|

Model

|

Double shaft shredder TS612

|

Four shaft shredder QS1012

|

|

Motor power (KW)

|

55

|

2*30+2*22

|

|

Cutting chamber (mm)

|

650*1250

|

1020*1200

|

|

Machine dimension (mm)

|

3380*2175*2600

|

4000*1260*650

|

Machine weight (Kg) | 5500 | 7500 |

Features of Harden's Waste Plastics Shredder

l Easy maintenance and safe operation

l Low noise and dust operation

l Knives are made of high-strength alloy, no worry of metal crushing

l Knives can be repaired by welding to reduce the maintenance cost

l Siemens and Schneider electric components ensure high stability

Video